520161

520071

520261

520001

520152

520254

520191

520252

in approx. 3 - 4 months available

in approx. 3 - 4 months available

520262

in approx. 2 - 3 months available

in approx. 2 - 3 months available

520911

in approx. 2 - 3 months available

in approx. 2 - 3 months available

520921

in approx. 2 - 3 months available

in approx. 2 - 3 months available

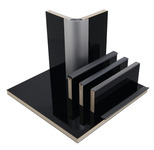

Why is HPL on almost all extension panels for motorhomes?

HPL is a synthetic resin mixture that stiffens the wood and gives it strength. Furniture construction boards made of poplar plywood are not only light, but also made of very soft wood. With a cheap foil coating, you will see clear signs of use on your motorhome construction board or, better, furniture construction board after only 1-2 years. The HPL laminate gives your furniture construction board the stability with which it can easily remain in the vehicle for 30 years.

What is HPL?

The name HPL comes from the English language: High Pressure Laminates. A carrier material of paper, cardboard or fabric is impregnated with various synthetic resins. In the case of our furniture construction boards, the resulting hard paper is pressed together with a poplar plywood board. By adding various resins, pressure and temperature, everything is joined together to form a stable furniture construction board. These furniture boards can withstand high temperatures for a short time without any problems. The resulting surface of the furniture boards is easy to maintain, easy to clean and withstands UV light. Scratch resistance, durability and a wide range of variants characterise these furniture boards and they are therefore perfectly suited for individual motorhome construction. More information about HPL can be found in the HPL boards Wikipedia.

Why "only" 0.6 mm HPL coating? Isn't thicker also tougher?

A thicker HPL coating would definitely make the surface of the HPL coated board even less sensitive. However, the furniture board for motorhomes made of plywood would also become tougher in the same step. The motorhome self-assembly is then only possible to a limited extent. Thick HPL coating makes the cut edges splinter very easily, the coated wood becomes unsightly and the HPL coating of your motorhome wood finishing would be defective even before use. A good processing of such a furniture panel with smooth cut edges can only be done with a professional tool. With any normal saw, the cut edges of the furniture board would flake off and tear out.

Furniture construction boards made of poplar plywood with HPL coating are characterised by

- Stability

- the fixtures can be screwed together in best quality

- easy processability

- low weight

- resistant surface

- good stiffness and fixing possibilities

- Longevity